What is Extrusion Blow Molding: The Ultimate Guide to It

About Author: Lucas Ji

Founder of UKPACK, Chief Packaging Designer with 18 years of experience, Red Dot Award Winner

Specialize in custom, innovative, and sustainable packaging solutions for cosmetics, skincare, personal care, hair care, food and beverage, and more.

Have you ever squeezed lotion from a soft plastic bottle and wondered how it was made?

Chances are, it came to life through a fascinating process called extrusion blow molding (EBM).

In the world of cosmetic packaging, understanding how your bottles, jars, and containers are produced is not just interesting. It is essential.

The right knowledge helps you make smarter design choices, cut production costs, and even improve your brand’s sustainability profile.

In this ultimate guide, we will break down everything you need to know about extrusion blow molding. From basic definitions to expert comparisons, practical examples, and insider tips for cosmetics packaging.

Let’s dive in.

What Is Extrusion Blow Molding?

Put simply, extrusion blow molding (EBM) is a manufacturing method for creating hollow plastic objects, such as bottles, jars, and containers.

The idea is surprisingly elegant.

Melted plastic is pushed (extruded) into a hollow tube called a parison.

While still hot, this tube is trapped inside a mold. Air is blown into it, just like blowing up a balloon, forcing the plastic to expand and take the shape of the mold. After cooling, the new object is released, ready to be trimmed and finished.

EBM is widely used across industries. In cosmetics, it is a go-to technique for producing everything from shampoo bottles to luxurious lotion containers.

Its versatility and cost-effectiveness make it an excellent choice for brands that want to combine style, durability, and scalability.

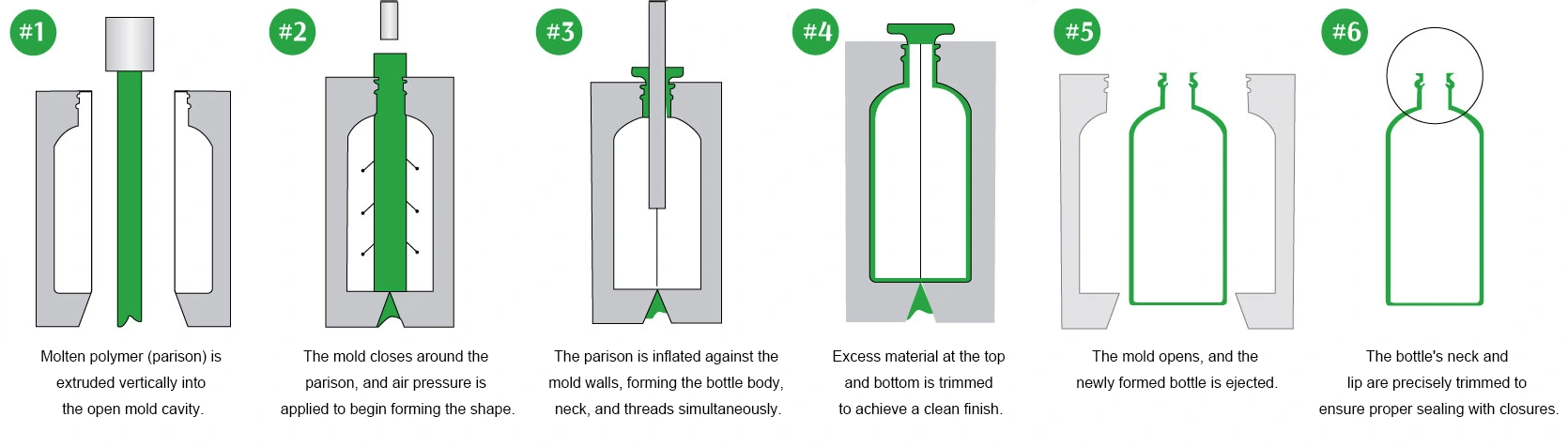

A Step-by-Step Breakdown of the Extrusion Blow Molding Process

To really understand extrusion blow molding, let’s walk through the key stages.

1. Plastic Melting

Plastic pellets, typically polyethylene (HDPE, LDPE) or polypropylene (PP), are fed into an extruder.

Inside, they are heated and transformed into a thick, molten state, similar to honey warming up in a pot.

2. Parison Extrusion

This molten plastic is squeezed through a die head, forming a long, hollow tube called a parison.

Imagine it like a sausage being extruded, soft and glowing hot.

3. Mould Closing and Pinch-Off

A two-piece mould, designed in the shape of the final product, snaps shut around the parison.

The bottom of the parison is pinched, sealing it and trapping the hot air inside.

4. Inflation (Blowing)

Air is injected into the parison using a blow pin or needle.

As the air pressure rises, the soft plastic expands outward, hugging the walls of the mould until it adopts the exact shape.

5. Cooling and Ejection

Cooling systems solidify the inflated plastic quickly.

Once hardened, the mould opens and the new part pops out, still attached to some excess material known as flash.

6. Trimming (Deflashing)

Cooling systems solidify the inflated plastic quickly.

Once hardened, the mould opens and the new part pops out, still attached to some excess material known as flash.

Pro Tip:

In high-end cosmetic packaging, careful control during the extrusion and blowing stages is critical to achieving uniform wall thickness and ensuring a premium “in-hand” feel.

Key Components in an Extrusion Blow Molding Machine

Behind the scenes, extrusion blow molding relies on several key components working together.

1. Extruder

This machine melts and pushes the plastic forward while maintaining precise temperature and pressure.

2. Die Head

It shapes the molten plastic into a parison. Special die designs can influence bottle thickness and performance, which is critical for cosmetics where feel and durability matter.

3. Blow Moulds

Two halves of a precision-engineered mould define the external shape of the product.

4. Blow Pins or Needles

These inject compressed air into the parison, inflating it into the mould cavity.

5. Cooling Systems

Rapid cooling prevents warping and helps achieve tight production cycles, essential for large-scale packaging orders.

Understanding these parts gives you a deeper appreciation for how cosmetic packaging is manufactured and why attention to detail at each stage matters so much.

Materials Commonly Used in Extrusion Blow Molding

Choosing the right material is crucial in extrusion blow molding, especially when designing cosmetic packaging. Different plastics offer unique advantages, whether it is about flexibility, clarity, chemical resistance, or sustainability. Let’s explore the most common materials used in the process.

1. HDPE (High-Density Polyethylene)

HDPE is one of the most widely used plastics in extrusion blow molding. It is strong, lightweight, and highly resistant to impact.

According to the Plastics Industry Association, HDPE is known for its high strength-to-density ratio.

You will often find HDPE used for products like shampoo bottles, body wash containers, and cleansing oil bottles. It has a slightly opaque finish that provides a natural, sturdy look, ideal for everyday cosmetic and personal care packaging.

2. LDPE (Low-Density Polyethylene)

LDPE offers a softer and more flexible option compared to HDPE. It is particularly suited for applications where easy squeezing is important, such as lotion bottles or cream tubes. Its flexibility ensures smooth dispensing without requiring pumps or complex closures, making it a preferred choice for many skincare lines.

3. PP (Polypropylene)

Polypropylene is valued for its excellent chemical resistance and high-temperature stability. It is commonly used for more technical cosmetic packaging, like cream jars, treatment serums, or products containing active ingredients.

PP often has a glossy surface, which gives a high-end, premium aesthetic that many luxury cosmetic brands appreciate.

4. PETG (Polyethylene Terephthalate Glycol)

PETG is a tough yet crystal-clear material. It is perfect for cosmetic containers where visibility and aesthetics matter, such as clear serum bottles, body oil containers, or decorative skincare jars.

PETG offers glass-like clarity while maintaining the lightweight and impact-resistant benefits of plastic.

5. Multi-layer Structures

For more advanced needs, extrusion blow molding can combine multiple layers of different materials into a single bottle.

For instance, a structure might include an inner layer of recycled material, a middle layer with EVOH for oxygen barrier protection, and an outer layer of virgin plastic for visual appeal.

Multi-layer packaging is especially important for sensitive cosmetic formulas that need extra protection from air and contamination.

Pro Tip:

When choosing materials for cosmetic packaging, always consider both the functional requirements and the brand image you want to project. A good extrusion blow molding partner can guide you through selecting the best resin or combination for your specific product.

Advantages of Extrusion Blow Molding

Extrusion blow molding has become a preferred method for producing hollow plastic containers, especially in the cosmetics industry. Its unique set of advantages makes it an attractive choice for brands that value flexibility, efficiency, and design freedom. Here are the key benefits you should know.

1. Lower Tooling Costs

Compared to other molding techniques, such as injection blow molding or injection stretch blow molding, extrusion blow molding typically requires less complex molds.

This means the initial investment in tooling is lower, which is ideal for cosmetic brands launching new products or custom lines.

Shorter lead times for mold development also allow quicker market entry.

2. Design Flexibility

Extrusion blow molding supports a wide range of creative bottle shapes and sizes.

Whether you want an ergonomic grip, an integrated handle, or a unique curved design for a lotion bottle, EBM can handle it.

The ability to create asymmetrical and non-standard geometries gives brands the freedom to innovate without significant manufacturing constraints.

3. Ability to Produce Multi-layer Packaging

EBM allows the production of containers with multiple material layers.

This feature is valuable for cosmetics that require enhanced protection against oxygen, moisture, or light.

For example, a cosmetic bottle might have an inner layer made from recycled material and an outer layer that maintains a premium finish.

This multi-layer capability supports both sustainability goals and product performance.

4. Efficiency for Medium to Large Volumes

Extrusion blow molding is highly efficient for medium and large production runs.

Once set up, the process can produce hundreds or thousands of containers per hour, depending on machine configuration and part size.

This efficiency helps maintain competitive unit costs, even for custom designs.

5. Compatibility with Recycled Materials

Modern EBM technology can easily incorporate post-consumer recycled (PCR) plastics into production.

For cosmetic brands aiming to boost their sustainability profile, using PCR materials within extrusion blow molded packaging offers a strong environmental message without sacrificing quality.

Table of Key Advantages

| Advantage | Explanation |

|---|---|

| Lower Tooling Costs | Simple mold designs mean lower upfront investment. |

| Design Flexibility | Supports complex shapes, integrated handles, and features. |

| Multi-layer Packaging Possibility | Enhances product protection with barrier layers. |

| High Production Efficiency | Suitable for mass production with consistent quality. |

| Use of Recycled Materials | Aligns with eco-friendly packaging initiatives. |

Insight:

By choosing extrusion blow molding, cosmetic brands can enjoy a rare combination of design creativity, cost control, and eco-friendly production options. Few other manufacturing methods offer this level of versatility.

Limitations and Challenges of Extrusion Blow Molding

While extrusion blow molding offers many advantages, it is important to understand its limitations too.

Being aware of these challenges helps in setting the right expectations and choosing the right manufacturing partner.

1. Flash Formation and Trimming Waste

During the moulding process, when the parison is pinched between the mould halves, extra plastic material known as flash is produced.

This flash needs to be trimmed in a secondary step, which adds an extra stage to the production cycle.

Although most of this scrap can be recycled and reused, brands focused on zero-waste initiatives may see this as a point to consider.

2. Slightly Lower Neck Precision

Compared to processes like injection blow molding or injection stretch blow molding, extrusion blow molding typically offers slightly less precision around the neck finish of the container.

For most cosmetic bottles, this small variation is not noticeable and does not affect functionality.

However, for products requiring extremely tight closure tolerances, such as high-pressure sprays or very small vials, other methods might sometimes be recommended.

3. Wall Thickness Control Complexity

Controlling wall thickness evenly throughout the container can be more challenging in extrusion blow molding compared to some other methods.

Without careful process control, this could lead to uneven weight distribution, which affects the bottle’s feel and strength.

Modern extrusion blow molding machines equipped with parison programming have largely overcome this issue, allowing skilled manufacturers to adjust the thickness dynamically as the parison is formed.

4. Material Restrictions for Certain Applications

Although extrusion blow molding works beautifully with materials like HDPE, LDPE, and PP, it is less suited for some specialty resins that require high clarity and extreme barrier properties.

For example, clear PET bottles for luxury serums are often better made through injection stretch blow molding instead.

Good to Know:

Experienced partners like UKPACK use advanced equipment and quality control systems to minimise these challenges.

With the right design expertise and production setup, extrusion blow molding can deliver consistently high-quality cosmetic packaging that meets both aesthetic and performance needs.

Extrusion Blow Molding vs Other Molding Methods: A Practical Comparison

When choosing the right manufacturing process for cosmetic packaging, it is important to understand how extrusion blow molding compares to other molding methods.

Each technique has its own strengths and best-use scenarios.

Let’s break it down clearly.

1. Extrusion Blow Molding (EBM) vs Injection Blow Molding (IBM)

1.1 Process Difference

In extrusion blow molding, molten plastic is extruded into a parison, then inflated inside a mould to form the final shape.

In injection blow molding, a preform is first injection molded, then reheated and blown into shape inside a second mould.

1.2 Precision and Surface Quality

Injection blow molding generally offers higher neck precision and better surface finishes.

This is because the neck area is injection molded in the first step, giving tight control over dimensions.

1.3 Cost and Flexibility

Extrusion blow molding has lower tooling costs and offers greater flexibility in bottle shapes.

It can easily produce containers with handles, off-centre necks, or more complex forms, which is difficult with injection blow molding.

1.4 Suitability for Cosmetic Packaging

For everyday cosmetic products like shampoo bottles, body washes, and lotions, extrusion blow molding is more cost-effective and versatile.

Injection blow molding is better suited for small, high-precision bottles, such as perfume atomizers or pharmaceutical vials.

2. Extrusion Blow Molding (EBM) vs Injection Stretch Blow Molding (ISBM)

2.1 Process Difference

Injection stretch blow molding also starts with a preform, but during blowing, the preform is stretched both axially and radially.

This stretching improves clarity, strength, and barrier properties.

2.2 Visual Appearance

ISBM is typically used when you need crystal-clear containers, such as PET bottles for high-end serums, beverages, or luxury skincare packaging.

2.3 Cost and Complexity

ISBM tooling and production setups are more expensive and require longer lead times compared to EBM.

It is less flexible in accommodating unusual shapes or built-in features like handles.

2.4 Suitability for Cosmetic Packaging

For clear, rigid cosmetic containers where visual transparency is critical, ISBM is preferred.

For larger, less clarity-dependent products like hair care bottles, EBM remains the smarter choice.

3. Extrusion Blow Molding (EBM) vs Injection Molding (for Solid Parts)

3.1 Process Difference

Injection molding is used to create solid plastic parts.

There is no hollow blowing stage involved.

3.2 Typical Applications

Injection molding is ideal for producing cosmetic caps, cream jars, compact cases, and solid closures where precision and surface finish are paramount.

3.3 Suitability for Cosmetic Packaging

Whenever the product needs to hold or dispense liquid, extrusion blow molding is more appropriate.

When producing solid parts like caps or intricate cosmetic jar lids, injection molding becomes the method of choice.

Comparison Summary Table

| Aspect | Extrusion Blow Molding (EBM) | Injection Blow Molding (IBM) | Injection Stretch Blow Molding (ISBM) | Injection Molding |

|---|---|---|---|---|

| Process | Extrude parison, inflate in mould | Inject preform, reheat, blow into mould | Inject preform, stretch and blow | Inject directly into solid mould cavity |

| Hollow or Solid Parts | Hollow containers | Hollow small containers | Hollow, clear containers | Solid parts only |

| Precision of Neck Finish | Moderate | High | High | Very high |

| Typical Materials | HDPE, LDPE, PP, PETG | PET, PP | PET | PP, ABS, SAN, PMMA |

| Mold Cost | Low | High | Very high | Medium |

| Flexibility of Shape | High | Limited | Limited | Very high for solid shapes |

| Best for Cosmetic Packaging | Bottles for hair care, body care, lotions | Small precision bottles, travel-sized vials | Clear serum bottles, luxury packaging | Caps, jars, compact cases |

Applications of Extrusion Blow Molding

Extrusion blow molding is a true workhorse in the world of plastic packaging.

Its ability to create hollow containers with complex shapes and cost-effective production makes it the ideal choice for a wide range of industries.

In cosmetics, personal care, and beauty packaging, extrusion blow molding plays an even more critical role.

1. Cosmetic Bottles and Containers

From daily essentials to premium skincare products, many cosmetic packaging formats are best produced through extrusion blow molding.

Common examples include shampoo bottles, body wash containers, lotion dispensers, and hair treatment packaging.

These products often require ergonomic shapes, comfortable grip features, and durable walls, all of which extrusion blow molding can deliver with ease.

2. Flexible Tottle Bottles for Skincare and Makeup

One outstanding application of extrusion blow molding is the production of custom tottle bottles.

Tottles are semi-rigid tubes that stand upside down, making it easy for consumers to dispense thick creams, gels, or lotions.

The flexibility combined with a stable flat cap design enhances user experience, especially for viscous products.

A real-world example is The Beauty Crop.

This dynamic beauty brand collaborated with UKPACK to develop their signature tottle bottles using advanced extrusion blow molding technology.

The goal was to create lightweight, flexible packaging that maintained a premium feel while being cost-effective and sustainable.

Through careful material selection and precision mold design, UKPACK helped The Beauty Crop achieve a perfect balance between functionality, aesthetics, and brand identity.

The project highlighted how extrusion blow molding can support innovative packaging designs without compromising production efficiency.

Case Insight:

The Beauty Crop’s successful launch of their skincare range with tottle bottles not only improved product usability but also strengthened the brand’s commitment to eco-conscious packaging solutions, something UKPACK continues to champion in the beauty industry.

3. Household and Personal Care Products

Beyond cosmetics, extrusion blow molding is also widely used for personal care items like hand soaps, sanitisers, and conditioners.

Its ability to create sturdy, impact-resistant containers makes it perfect for everyday household applications.

4. Industrial and Medical Packaging

In more technical sectors, such as pharmaceuticals and industrial products, extrusion blow molding is chosen for items like medical squeeze bottles, lubricant containers, and large-capacity canisters.

The process supports strict quality requirements, especially when advanced barrier layers are needed to protect sensitive formulations.

Innovations in Extrusion Blow Molding for Cosmetic Packaging

The cosmetics industry is evolving faster than ever.

Brands are no longer just looking for attractive packaging. They are demanding solutions that are lighter, greener, and smarter.

Extrusion blow molding has kept pace with these changes, offering exciting innovations that meet the new needs of modern beauty brands.

1. Lightweight Bottle Design

Reducing packaging weight without compromising strength or functionality has become a top priority.

Through advanced mould design and precision material control, extrusion blow molding now enables the creation of thinner-walled bottles that are still durable and user-friendly.

Lightweight packaging can significantly reduce environmental impact, as supported by data from the Environmental Protection Agency (EPA).

Lighter packaging not only saves material but also lowers transportation costs and reduces carbon emissions.

At UKPACK, our engineering team works closely with brands to optimise wall thickness during the blowing stage.

The result is cosmetic bottles that feel premium yet use less plastic, supporting both economic and environmental goals.

2. Use of Post-Consumer Recycled (PCR) Materials

Sustainability is no longer optional in the beauty world.

Modern extrusion blow molding technology can incorporate high percentages of PCR plastics, such as recycled HDPE or recycled PP, into cosmetic packaging.

These materials maintain excellent performance while significantly reducing environmental impact.

UKPACK actively promotes the integration of PCR materials into our extrusion blow molded products.

We help our clients not only meet regulatory requirements but also tell a genuine sustainability story that resonates with conscious consumers.

3. Barrier Layer Technology for Sensitive Formulations

Sensitive cosmetic formulas, like serums, organic skincare, or essential oils, often require additional protection against oxygen, UV light, or moisture.

Multi-layer extrusion blow molding makes it possible to add barrier layers, such as EVOH, within the bottle walls.

This innovation ensures that products stay fresh longer without relying on heavy or non-recyclable packaging.

UKPACK has developed custom multilayer solutions that combine PCR materials with high-performance barrier layers.

For example, our extrusion blow molded tottle bottles can be manufactured with up to six distinct layers.

Compared to traditional five-layer structures, our six-layer design offers a more efficient material distribution, helping brands save on raw material costs without compromising product protection.

This advanced structure allows us to optimise both the inner and outer surfaces for formula compatibility and visual aesthetics, while embedding functional barrier layers in between for maximum performance.

This hybrid approach ensures both sustainability and product integrity, offering brands a competitive and cost-effective advantage in the market.

4. New Surface Treatments and Textures

Beyond structural improvements, extrusion blow molding also allows for creative surface finishes.

Matte effects, soft-touch coatings, and custom textures can now be incorporated directly during moulding or through post-processing.

These tactile enhancements give cosmetic packaging a more luxurious feel and strengthen brand identity on retail shelves.

UKPACK continuously invests in new surface treatment technologies.

We help beauty brands deliver not just a better product experience but also a stronger emotional connection with their customers.

How UKPACK Uses Extrusion Blow Molding to Create Premium Cosmetic Packaging

At UKPACK, we see extrusion blow molding as more than just a manufacturing method.

It is a tool that helps beauty brands turn their creative ideas into real, high-performing products.

Take The Beauty Crop as an example.

When they approached us to develop a flexible, lightweight tottle bottle for their skincare range, they needed more than just a supplier.

They needed a partner who could balance aesthetics, sustainability, and cost.

Through our advanced six-layer extrusion blow molding process, we helped them create packaging that not only looked beautiful but also protected sensitive formulas and supported their eco-conscious goals.

At every step, from material selection to mould design, UKPACK focuses on the small details that make a big difference.

We believe packaging should not just meet expectations. It should elevate the brand and delight the consumer.

Ready to create cosmetic packaging that stands out?

Get in touch with UKPACK today and let’s bring your vision to life.

Frequently Asked Questions (FAQ)

1. What products are typically made using extrusion blow molding?

Extrusion blow molding is mainly used to create hollow plastic items, such as bottles, jars, and containers.

In cosmetics, it is commonly used for shampoo bottles, lotion dispensers, body wash containers, and flexible tottles.

2. Which plastics are most suitable for cosmetic packaging made with extrusion blow molding?

The most commonly used plastics are HDPE, LDPE, PP, and PETG.

These materials offer a balance of strength, flexibility, and chemical resistance, making them perfect for beauty and personal care products.

3. How can I tell if a bottle was made by extrusion blow molding?

One simple clue is the presence of a fine line along the bottom or sides of the container.

This mark comes from where the mould halves joined together and is typical for extrusion blow molded products.

Some tottles and bottles may also show a slight pinch-off point, which is normal and does not affect performance.

4. What are the benefits of using a multilayer structure in cosmetic packaging?

Multilayer structures offer enhanced protection for sensitive formulas.

Barrier layers, such as EVOH, block oxygen, moisture, and UV light, helping products stay fresh longer.

At UKPACK, we can create up to six-layer bottles that combine sustainability, premium aesthetics, and technical performance.

5. Is extrusion blow molding compatible with recycled materials?

Yes, modern extrusion blow molding easily incorporates post-consumer recycled (PCR) plastics like recycled HDPE or recycled PP.

UKPACK actively promotes the use of PCR materials to help brands meet their sustainability goals while maintaining product quality.

6. When should I choose extrusion blow molding instead of other manufacturing methods?

If you need a cost-effective solution for producing medium to large volumes of hollow containers, extrusion blow molding is a great choice.

It is ideal for cosmetic bottles that need design flexibility, moderate clarity, and good durability.

For solid parts or extremely clear bottles, other methods like injection molding or injection stretch blow molding might be better suited.

7. Can UKPACK customise bottle shapes and surface finishes through extrusion blow molding?

Absolutely.

At UKPACK, we offer full customisation services, from mould design to surface treatment options.

Whether you need a matte texture, a glossy finish, or a unique ergonomic shape, our team can help you bring your vision to life.