What Is a Tottle Bottle? The Ultimate Guide to This Unique Packaging Solution

About Author: Lucas Ji

Founder of UKPACK, Chief Packaging Designer with 18 years of experience, Red Dot Award Winner

Specialize in custom, innovative, and sustainable packaging solutions for cosmetics, skincare, personal care, hair care, food and beverage, and more.

If you’ve ever used a squeezable sunscreen or a foundation that stands upside down, chances are you’ve encountered a tottle bottle. This unique hybrid packaging combines the best features of a tube and a bottle, offering convenience and efficiency. But what exactly is a tottle bottle, and why is it gaining popularity in the beauty and personal care industry? Let’s dive in!

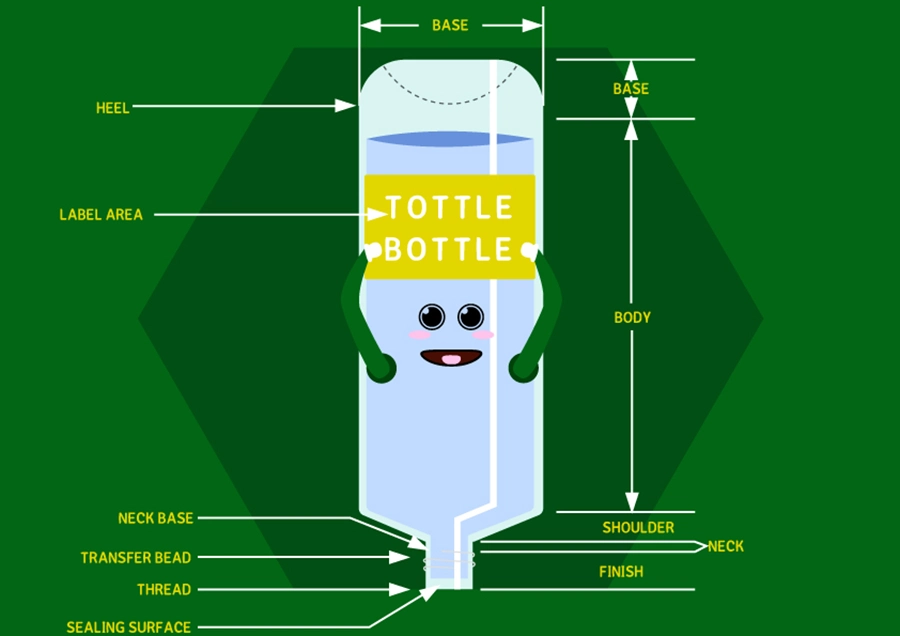

The Design of a Tottle Bottle

A tottle bottle is designed to stand on its cap, allowing easy dispensing of thick formulations. It features a semi-rigid body that can be squeezed, ensuring that the product flows out smoothly without excessive effort. Unlike traditional tubes, which require squeezing from the bottom, tottles use gravity-assisted dispensing, making them highly efficient.

Materials Used in Tottle Bottles

Tottle bottles are typically made from durable plastics such as:

- Polypropylene (PP) – Lightweight and recyclable

- Polyethylene (PE) – Flexible and soft-touch for better squeezability

- Polyethylene Terephthalate (PET) – Offers a premium, glossy finish

For brands focused on sustainability, post-consumer recycled (PCR) plastics and biodegradable materials are becoming increasingly popular options.

Production Process

Common Layer Structures of Tottle Bottles

Tottle bottles are a flexible packaging option that offers the advantages of both tubes and bottles, making them perfect for personal care and cosmetic products. Knowing the different layer structures of tottle bottles helps you choose the best packaging for your products, ensuring they are well-protected and easy to use.

Single Layer Structure

Single-layer tottle bottles typically come in three material options, each offering unique advantages and suitability for your products. Choosing the right material based on your product’s needs can enhance user experience and ensure product stability.

HDPE (High-Density Polyethylene)

- Advantages: Low cost, lightweight, and easy to produce.

- Disadvantages: Higher hardness may lead to a less pleasant hand feel and increased risk of cracking.

LDPE (Low-Density Polyethylene)

- Advantages: Soft, easy to squeeze, and convenient to use.

- Disadvantages: Less suitable for printing, which may result in unclear graphics or text, and weaker protective performance.

PET (Polyethylene Terephthalate)

- Advantages: Excellent transparency and strong oxidation resistance, making it suitable for a variety of products.

- Disadvantages: Not suitable for sunscreen products and is more susceptible to environmental factors.

2-Layers Structure

2-layers structure tottle bottles typically combine HDPE and LDPE, with HDPE as the outer layer and LDPE as the inner layer.

Material Composition:

- Outer Layer (HDPE): Provides strength and moisture resistance.

- Inner Layer (LDPE): Offers flexibility and a soft feel for easy squeezing.

Advantages:

- Better User Experience: Comfortable grip and easy dispensing.

- Enhanced Printability: Smooth HDPE surface allows for high-quality printing.

- Balanced Durability and Flexibility: Combines strength and ease of use.

Applications:

- Suitable for personal care, cleaning products, and food items, appealing to brands focused on user-friendly packaging.

Potential Disadvantages:

- Higher Costs: Dual materials may increase production expenses.

- Recycling Challenges: The combination can complicate recycling processes.

3-Layers Structure

The 3-layer structure of tottle bottles typically consists of three distinct layers designed to enhance both functionality and aesthetic appeal.

- Innermost Layer: Made from food-grade LDPE, ensuring safety for contact with the contents.

- Middle Layer: Composed of an adhesive layer that bonds the inner and outer layers, enhancing overall structural integrity.

- Outer Layer: Usually consists of EVOH for effective oxygen barrier properties, or may utilize materials like HDPE or PP for a more rigid structure, although HDPE and PP are less common in this application. Additionally, Soft Touch finishes can be employed for a premium feel.

This layered design effectively balances cost and performance, making it suitable for a wide range of cosmetic products.

Common applications of 3-layer tottle bottles include sunscreens and vitamin C serums, as they require enhanced protection against oxidation and light.

5-Layers Structure

The 5-layer structure of tottle bottles is designed for optimal performance and protection, particularly for products containing highly active ingredients.

- Innermost Layer: Composed of medical-grade PE (Polyethylene), ensuring the safety of the contents.

- Adhesive Layer: This layer is incorporated to create a strong bond between the innermost layer and the subsequent layers.

- EVOH Layer: Provides robust barrier protection against oxygen and moisture, essential for preserving product integrity.

- Another Adhesive Layer: Enhances the structural integrity of the bottle by securely bonding the EVOH layer to the outer layers.

- Outer Layer: Features a soft touch coating or may utilize HDPE (High-Density Polyethylene) for added durability and a premium tactile experience.

This advanced multi-layer design offers excellent protection, making it particularly suitable for products like retinol serums and anti-aging formulations found in well-known brands.

6-Layers Structure

The 6-layer structure of tottle bottles is engineered to provide superior protection, particularly for sensitive ingredients and products used in extreme environments.

- Innermost Layer: Composed of PE (Polyethylene), ensuring safety for the contents.

- Recycled Layer: This layer incorporates recycled materials, allowing for the inclusion of ground head and tail materials, which is not possible in 5-layer structures.

- Adhesive Layer: Creates a strong bond between the recycled layer and the EVOH layer.

- EVOH Layer: Serves as an effective barrier, preventing light, moisture, and oxygen from compromising the contents.

- Another Adhesive Layer: Enhances the structural integrity of the bottle by securely bonding the EVOH layer to the outer layers.

- Outer Layer: The outermost layer can be made from PE, PP (Polypropylene), or feature a soft touch coating, providing impact resistance and a premium tactile experience.

While the cost of 6-layer structures is generally lower than that of 5-layer designs, this technology is currently less common. At UKPACK, we are equipped to efficiently produce 6-layer tottle bottles, ensuring high-quality output suitable for various applications.

Key Benefits of Tottle Bottles

- Controlled Dispensing – The semi-rigid body ensures precise product flow, reducing waste.

- Squeezable Convenience – Allows users to extract product effortlessly.

- Space-Saving Design – The upright standing design is compact and ideal for retail displays.

- Leak-Proof & Travel-Friendly – Secure closures prevent spills, making them perfect for on-the-go use.

Common Uses of Tottle Bottles

Tottle bottles are widely used in:

- Skincare – Sunscreens, lotions, serums

- Haircare – Conditioners, styling gels

- Cosmetics – Foundations, BB creams, primers

- Personal Care – Hand sanitizers, shower gels

Their versatile nature makes them a go-to packaging solution for both luxury and mass-market brands.

How Tottle Bottles Improve Product Performance

Tottle bottles have gained popularity in recent years, particularly in industries such as cosmetics, personal care, and food. Unlike traditional tubes, which can sometimes leave users frustrated with leftover product stuck at the bottom, tottle bottles are designed to maximize product usage efficiently. Their unique design offers several advantages that significantly enhance product performance and user experience.

1. Gravity-Assisted Design

Tottle bottles utilize a gravity-assisted design, allowing thick formulas to flow smoothly toward the opening and reducing the effort needed to dispense the product. This feature is particularly beneficial for users who may struggle with traditional tubes, ensuring every last drop can be easily accessed.

2. Reduced Waste

These bottles are engineered to maximize product extraction, significantly decreasing waste compared to conventional packaging. As a result, consumers enjoy better value for their purchases while contributing to more sustainable consumption patterns.

3. User-Friendly Experience

Designed with ergonomics in mind, these bottles allow for easy squeezing and precise control over product dispensing. This user-friendly approach makes them ideal for various settings, whether at home or on the go.

4. Enhanced Product Longevityriendly Experience

The design effectively minimizes air exposure, which can lead to oxidation and spoilage of the product inside. Consequently, consumers can enjoy their formulations for a longer period without compromising quality.

5. Aesthetics and Branding Opportunities

This packaging format offers brands the chance to create eye-catching designs that stand out on store shelves. The transparent or semi-transparent materials allow consumers to see the product level, fostering trust and enhancing brand loyalty.

Tottle Bottles vs. Traditional Bottles and Tubes

| Feature | Tottle Bottle | Traditional Bottle | Squeeze Tube |

|---|---|---|---|

| Squeezable | Yes | No | Yes |

| Stands Upright | Yes | Yes | No |

| Controlled Dispensing | Yes | No | Limited |

| Travel-Friendly | Yes | Depends | Yes |

Customizing Tottle Bottles for Branding

Brands can personalize tottle bottles through:

- Custom colors and finishes (matte, glossy, frosted)

- Logo printing options (silk-screen, hot stamping, labeling)

- Variety of caps (flip-top, pump, screw cap)

Eco-Friendly Tottle Bottle Options

As sustainability becomes an increasingly critical focus for both consumers and brands, the packaging industry is responding with innovative solutions, including eco-friendly tottle bottle options. These alternatives not only meet environmental standards but also align with the values of eco-conscious consumers. Here are some key eco-friendly features of modern tottle bottles:

1. Mono-Material Tottles for Easier Recycling

Mono-material tottle bottles are made from a single type of plastic, simplifying the recycling process. This design allows for more efficient recycling, reducing the amount of waste that ends up in landfills.

2. Post-Consumer Recycled (PCR) Plastic to Reduce Virgin Plastic Use

Using post-consumer recycled (PCR) plastic decreases reliance on virgin materials derived from fossil fuels. This approach not only lessens the carbon footprint of production but also supports the recycling industry by creating demand for recycled products.

3. Biodegradable Alternatives for Eco-Conscious Consumers

Biodegradable tottle bottles are designed to break down more easily in natural environments, reducing their long-term ecological impact. Made from organic materials, these bottles appeal to consumers looking to minimize their environmental footprint.

4. The Importance of Certifications and Labels

Certifications such as “Recyclable” or “Biodegradable” provide transparency and assurance to consumers about the sustainability of packaging. These labels help consumers make informed choices while reinforcing brands’ commitments to environmental responsibility.

5. Consumer Education and Awareness

Educating consumers about the benefits of eco-friendly tottle bottles is essential for promoting sustainable practices. Clear labeling and informative marketing empower consumers to make responsible purchasing decisions and foster a community focused on sustainability.

Choosing the Right Tottle Bottle for Your Product

When selecting the ideal tottle bottle for your product, it’s crucial to consider various factors that can impact usability, safety, and consumer experience. Here are the key elements to take into account:

1. Product Viscosity

The viscosity of your formulation is critical in selecting a suitable tottle bottle, as thicker products require squeezable designs for easy dispensing. Conversely, lower viscosity products need softer bottles to ensure smooth flow and optimal user experience.

2. Material Compatibility

Choosing the right material for your tottle bottle is essential to ensure it is compatible with your formulation and does not react negatively. Materials like polyethylene (PE) or polypropylene (PP) are commonly used for their safety and effectiveness in packaging cosmetic and personal care products.

3. Closure Type

The closure type significantly affects the convenience and functionality of the packaging, with flip-top caps offering one-handed access for everyday items. In contrast, pump dispensers provide a premium feel and controlled dispensing, ideal for high-end products.

4. Size and Capacity

The size and capacity of the tottle bottle should match the product’s intended use and consumer preferences, with smaller sizes appealing to travelers and larger sizes being more cost-effective for regular use. Assessing market demand will help determine the optimal size for your product.

5. Design and Aesthetics

The visual appeal of the tottle bottle significantly impacts consumer perception and brand identity, making attractive designs crucial for shelf presence. Incorporating transparent materials can also enhance consumer trust by allowing them to see the product level.

6. Sustainability Considerations

Opting for eco-friendly materials can set your product apart in a competitive market, appealing to environmentally conscious consumers. Providing clear recycling information further demonstrates your commitment to sustainability and encourages responsible disposal practices.

Manufacturing and Filling Process of Tottle Bottles

The manufacturing and filling process of tottle bottles is a comprehensive operation that involves several key stages to ensure high-quality, functional packaging. Here’s a detailed overview of each step:

1. Injection Molding

The production of tottle bottles starts with injection molding, where melted plastic granules are injected into a mold to create the desired shape. This method ensures precise dimensions and thickness, resulting in consistent and defect-free bottles.

2. Decoration

After molding, the bottles undergo decoration, which includes printing, labeling, or coloring to enhance visual appeal and brand recognition. Various printing techniques and automated labeling machines are used to apply logos and product information accurately.

3. Filling

In the filling stage, specialized machines dispense the product into the bottles, accommodating various viscosities to ensure the correct volume is filled. This process is closely monitored to minimize spillage and maintain product integrity during filling.

4. Sealing & Packaging

Once filled, the bottles are sealed with caps using automated capping machines, ensuring product safety and freshness. After sealing, the bottles undergo a final inspection before being packaged for distribution, ready for delivery to retailers or consumers.

5. Quality Control

Stringent quality control measures are implemented throughout the manufacturing process, with routine checks at each stage to ensure adherence to safety and durability standards. Testing for leaks and material integrity is critical to prevent issues during transportation and use.

6. Sustainability Practices

Modern manufacturing increasingly incorporates sustainability practices, such as energy-efficient machinery and waste reduction initiatives. Many manufacturers are exploring the use of recycled materials to minimize environmental impact, aligning with consumer expectations for eco-friendly products.

Challenges and Limitations of Tottle Bottles

1. Limited for Very Liquid Formulas

Tottle bottles are typically designed to accommodate thicker products, such as creams and lotions, which can be easily dispensed through a squeeze mechanism. For very liquid formulas, such as runny liquids or serums, tottle bottles may not provide optimal dispensing control, leading to potential waste and difficulty in achieving the desired amount. This limitation can restrict their use for certain applications, as consumers may prefer alternative packaging solutions like pump bottles or droppers that are better suited for thinner formulations.

2. Higher Production Costs

The manufacturing process for tottle bottles can involve higher production costs compared to simpler packaging options like standard squeeze tubes. This is due to several factors, including the complexity of the injection molding process, the need for specialized machinery for filling and sealing, and potentially more expensive materials that ensure flexibility and durability. Consequently, these increased costs can affect the overall pricing strategy for products packaged in tottle bottles, making them less competitive in price-sensitive markets.

3. Design Constraints

While tottle bottles offer a unique aesthetic appeal, their design can present challenges in customization. Creating custom shapes or sizes may involve additional design and tooling costs, which can be prohibitive for smaller brands or limited production runs. Additionally, the need for compatibility with specific filling and sealing equipment may further restrict design options, limiting creativity and innovation in packaging. Brands must carefully balance their design aspirations with practical manufacturing considerations, which can sometimes lead to compromises in the final product appearance or functionality.

Future Trends in Tottle Bottle Packaging

1. Increased Sustainability

As environmental concerns continue to rise, the future of tottle bottles will see a significant shift towards sustainability. More brands are opting for recyclable materials, such as post-consumer recycled plastics or biodegradable alternatives, that minimize their ecological footprint. Additionally, companies are increasingly focusing on reducing packaging waste through innovative designs that use less material without compromising functionality. This trend is driven by consumer demand for eco-friendly products, prompting brands to adopt sustainable practices throughout their supply chains, from sourcing materials to manufacturing and distribution.

2. Innovative Dispensing Mechanisms

The advancement of technology is paving the way for innovative dispensing mechanisms in tottle bottles that enhance user experience and product preservation. One notable trend is the development of airless tottles, which eliminate air exposure to the product, thereby extending shelf life and maintaining product integrity. These airless systems prevent contamination and oxidation, making them particularly appealing for sensitive formulations, such as cosmetics and high-value skincare products. As brands seek to provide added value to consumers, these dispensing innovations will become increasingly popular, offering convenience and improved functionality.

3. Premium Aesthetics

With the growing emphasis on branding and consumer experience, tottle bottles are expected to feature enhanced aesthetics that reflect premium quality. Manufacturers are investing in advanced finishing techniques, such as matte or gloss coatings, textured surfaces, and metallic accents, to elevate the visual appeal of their packaging. Additionally, custom labeling and printing options will allow brands to create distinctive designs that resonate with target audiences, making their products stand out on the shelves. As competition intensifies, the emphasis on premium aesthetics not only enhances brand identity but also plays a crucial role in attracting consumers and fostering brand loyalty.

Conclusion

Tottle bottles offer a perfect blend of functionality, convenience, and style, making them a top choice for skincare, cosmetics, and personal care brands. Their ability to enhance user experience while minimizing product waste makes them an innovative packaging solution for modern consumers.

If you’re looking for high-quality tottle packaging tailored to your needs, UKPACK is here to provide you with a wide range of customizable options. Whether you require unique designs, sustainable materials, or innovative dispensing solutions, our team is dedicated to delivering the perfect tottle packaging that aligns with your brand values and enhances your product’s appeal. Contact UKPACK today to explore how we can help elevate your products with our tottle packaging expertise!