Custom Syrup Pump Manufacturer in China

UKPACK designs and manufactures high-performance and food-grade syrup pumps, sauce pumps, and condiment pumps in various neck finishes and models. Our products are widely used for dispensing flavored syrup, sauce, ketchup, honey, jam, salad dressing, condiment, and more.

With the latest technology at our disposal, our syrup dispensing pumps deliver excellent durability, precise output control, long lifespan, exceptional corrosion resistance, and more. We also offer both OEM and ODM services to cater to your specific requirements. From custom colors and printing to personalized packaging, we’ve got you covered.

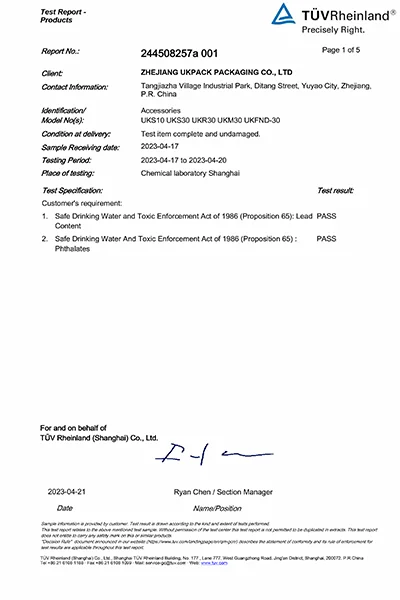

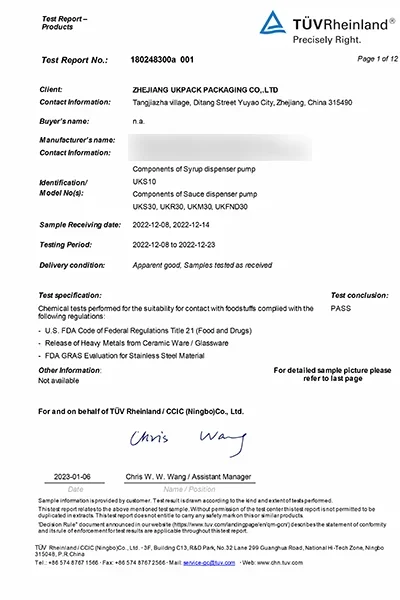

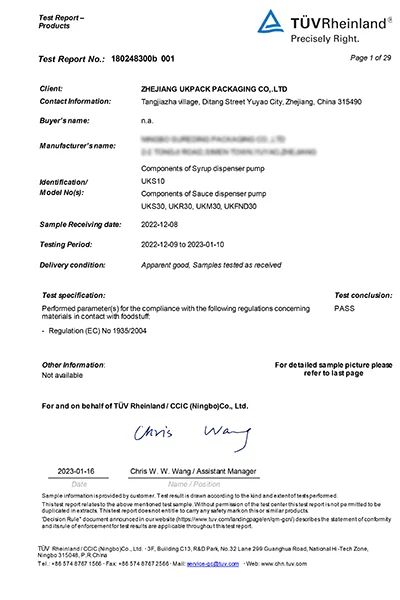

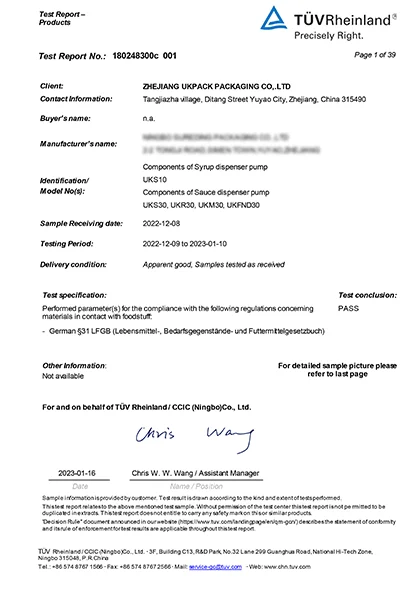

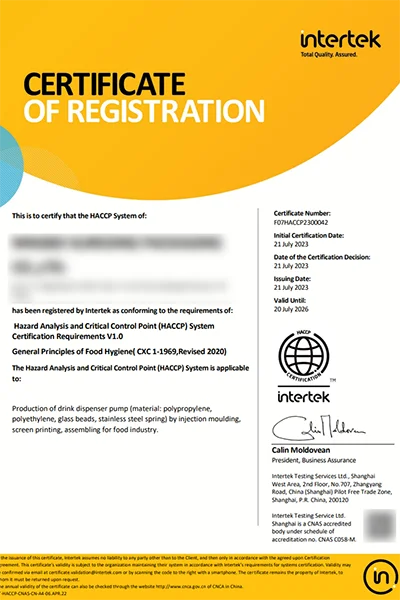

Rest assured, our syrup dispenser pumps have undergone rigorous testing and hold FDA report, GARS, FSSC, and HACCP certifications. We prioritize your safety and the integrity of your products.

Our products have earned the trust of renowned flavored syrup brands such as Torani, Monin, Berlin Packaging, AGRANA, TricorBraun, Döhler, Dolfi, By The Cup, Spoom, Hawthorne, and many more. When it comes to quality, they know they can count on UKPACK.

For your upcoming project that requires a syrup pump or viscous liquid pump, please contact us. Then, explore how we can help you with your dispensing pump needs.

Test Reports and Certifications

OEM Syrup Pump By Models

Why Choose UKPACK as your Syrup Pump Vendor

Food-grade PP Plastic Material

UKPACK manufactures a high-quality syrup pump using food-grade PP plastic. The raw material for our polypropylene (PP) includes Mobil’s PP1304, AP03B, and HMA025, all of which are sourced from the USA or Saudi Arabia. It ensures safety and meets strict food-contact standards. The material’s durability maintains syrup integrity and flavor. It’s a hygienic solution for the food and beverage industry, delivering a delightful experience with each use. Trust UKPACK’s reputation for excellence in producing this reliable and efficient syrup pump.

Our Syrup Dispensing Pump for Different Industries

Coffee Syrup Pump

Our coffee syrup pump is designed to expertly dispense flavorful syrups into your favorite coffee beverages. With precise portion control, it delivers the perfect amount of sweetness, enhancing the taste of your drinks consistently. Embrace the convenience and efficiency of our user-friendly coffee syrup pump, elevating your coffee shop or home brewing setup to a new level of excellence. Craft the perfect coffee creations with our reliable and food-grade syrup pump, making it an essential tool for every coffee lover and barista alike.

Syrup Pump for Ketchup

Say goodbye to messy squeeze bottles and tedious portioning – our ketchup syrup pump revolutionizes the way you serve and enjoy your favorite condiments. Experience precise portion control as our pump dispenses just the right amount of ketchup with each pump, eliminating wastage and ensuring consistent flavors in every dish. Whether you’re running a busy restaurant, hosting a backyard barbecue, or enjoying a family meal, our user-friendly ketchup syrup pump makes serving a breeze.

Concentrated Liquid Pump Dispenser for Car Washing Soap

Say goodbye to messy and inaccurate measurements. Our dispenser is designed to deliver the perfect amount of concentrated soap with just a simple pump. No more guesswork or spills – just the right amount of soap every time! This cutting-edge product is designed to revolutionize the way you clean your vehicle, providing you with unmatched convenience, precision, and eco-friendliness.

Sauce Pump for Chocolate

Elevate your dessert creations, beverages, and treats with this easy-to-use and efficient sauce pump. Say goodbye to messy pouring and hello to precision dispensing! Whether you’re a home baker, café owner, or chocolatier, our Sauce Pump for Chocolate is a game-changer that adds convenience and finesse to your culinary creations. So why wait? Elevate your chocolate experience and make every drizzle, swirl, and topping a work of art with our reliable and user-friendly sauce pump.

Condiment Dispenser Pump

The condiment dispenser pump is designed to revolutionize the way you serve and enjoy your favorite condiments. Whether it’s ketchup, mustard, mayo, salad dressings, hot sauces, or any other liquid condiment, this pump ensures effortless dispensing and mess-free usage. Upgrade your dining experience and say goodbye to messy condiment bottles with the condiment dispenser pump. It’s the perfect addition to any kitchen, offering convenience, hygiene, and precision in every serving.

Related Products

One-stop Syrup Pump Factory for Your Business

if you’re looking for a reliable and efficient solution for your syrup pump, sauce pump, condiment pump, or any other pumping requirements, look no further. Partner with us and experience the convenience of a comprehensive one-stop solution tailored to your needs. Let us help you take your project to new heights with our exceptional pumping solutions. Contact us today and embark on a seamless journey towards success!

Our Partner