Luxury Cosmetic Aluminum Airless Bottles for Lotion, Cream, Serum, Essence

Material: AS, aluminum, PP, ABS

Size: 10ml, 20ml, 15ml, 30ml, 50ml, 80ml, 100ml

Dosage: 0.23 +/- 0.02ml

Color: Customized color

Logo & Print: custom logo and print available

Usage: cream, lotion, essence, serum, skin care, etc

Feature: Aluminum, luxury, durable, lightweight

MOQ: 10000pcs

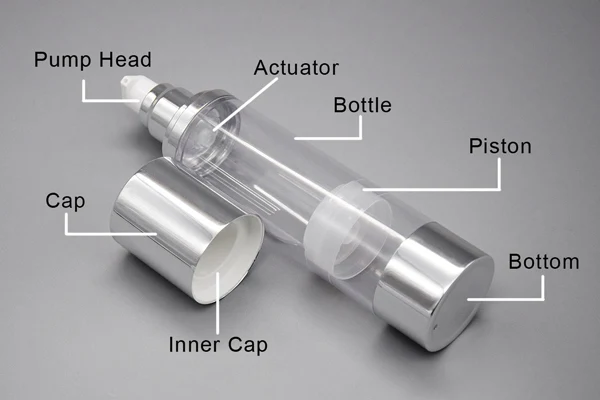

What Are Aluminum Airless Bottles?

Aluminum airless bottles come in a variety of shapes and sizes, but they all have one thing in common: they are airless. But they are made with a combination of AS and PP plastic materials, but the cap and bottom are covered with aluminum shells.

There is a non-pressurized vacuum dispensing system in aluminum airless bottles. When you press the pump head, the position will rise to push the product out of the pump.

These airless pump bottles are ideal for products that are sensitive to air and light, such as serums, lotions, and creams. They help to preserve the quality of the product and extend its shelf life.

And there are several reasons why aluminum airless bottles are the best choice for cosmetic and skincare products.

- They offer a high level of protection from air and moisture, which can damage delicate cosmetics and skincare products.

- They are light weight and easy to transport, making them ideal for travel.

- They are highly durable and resistant to breakage, making them a great choice for products that will be used often.

- They have a sleek, modern look that is perfect for cosmetic and skincare products.

UKPACK provides the best aluminum airless pump bottles to satisfy your specific needs.

The Capacities of Aluminum Airless Bottles

UKAPCK provides various capacities of aluminum airless bottles, which can be used for different applications. We have 10ml, 15ml, 20ml, 30ml, 50ml, 80ml, 100ml, and 120ml bottles available, so you can choose the right size for your needs.

We’re committed to providing products that meet your needs and exceed your expectations.

| Size | OD | Height |

|---|---|---|

| 10ml | 27mm | 97mm |

| 15ml | 27mm | 111mm |

| 20ml | 33mm | 108mm |

| 30ml | 33mm | 124mm |

| 50ml | 33mm | 155mm |

| 80ml | 40mm | 155mm |

| 100ml | 40mm | 177mm |

| 120ml | 40mm | 195mm |

How Do Aluminum Airless Bottles Work?

Aluminum airless bottles are made up of two main parts: an inner chamber and an outer chamber. The inner chamber holds your product, while the outer chamber is made up of an airtight seal. This seal keeps air from getting into the bottle and mixing with what’s inside, so your product stays pure and fresh.

When you press down on the pump, it pushes against this seal and creates a vacuum in between them—that’s what draws out your product! The pressure of this vacuum also makes sure no air gets in there either (so no oxidation).

Gravity doesn’t play a role in how aluminum airless bottles dispense product – so you can hold them in any orientation and still get the same amount of product out. Whether you’re holding it upside-down, sideways, or at any angle, the product will flow out evenly. This makes them very convenient to use, as you don’t have to worry about orienting the bottle in a certain way to get the product out.

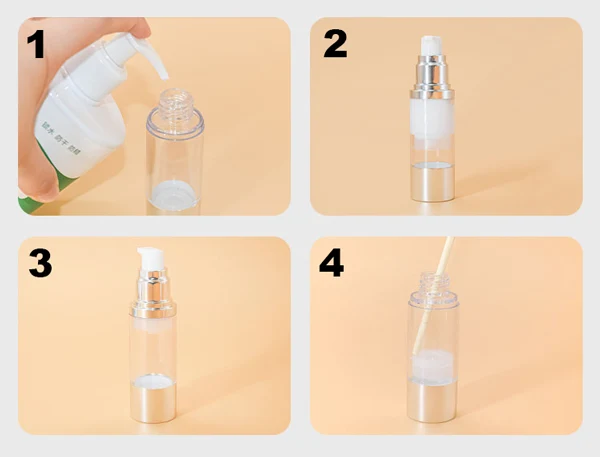

How to Use Aluminum Airless Bottles?

Our aluminum airless bottles are recycling available. There are 4 steps to use them.

- Pour your lotion or cream into the vacuum bottle until it is full.

- Press the pump head to discharge the air in the bottle, and the piston will move upwards to bring the lotion or cream out.

- When your lotion or cream is used up, the piston is at the top of bottle, and there is no residue in the bottle.

- When you want to refill the bottle, you just need to push the piston down to the position you want and pour your lotion or cream again.

If you want to learn more about it, please click the button below and get a quick quote.

How to Refill Aluminum Airless Bottles?

Have a question about how to refill aluminum airless bottles? You come to the right place. This video will show you how to refill it and use it again.

UKPACK provides refillable airless bottles in a variety of shapes, designs, capacities, colors, and surface finishes. We can create the right products to match your specifications.

Custom OEM & ODM Service

UKPACK offers one-stop custom OEM and ODM service for aluminum airless bottles.

A wide range of customization services are as follows: materials, sizes, colors, surface finishes, shapes, and more.

- Materials – PP, AS, Aluminum

- Capacities – For UKA31, it has 10ml, 15ml, 20ml, 30ml, 50ml, 80ml, 100ml, and 120ml. If you want other capacities, we have other airless bottles for you.

- Colors – Default color is silver aluminum and clear body, we can custom any colors according to your specifications.

- Surface finishes – most popular methods are screen printing, hot stamping, and label sticker.

Get a quick quote, and learn more about our cosmetic packaging services.

Where to Buy Aluminum Airless Bottles?

UKPACK is a professional manufacturer of aluminum airless bottles in China. With over 10 years of experience, we provide high-quality and cost-effective products. We are committed to providing our customers with the best possible products and services. We strive to be the best in the industry, and we are constantly innovating and improving our products and services. We are the perfect partner for your packaging needs.

Client Testimonials

Don’t take our word for it, read the feedback from some of our clients.

Aluminum Airless Bottles: The Ultimate FAQ Guide

If you’re looking for an aluminum airless bottle guide, you’ve come to the right place.

In this guide, we’ll cover everything you need to know about these types of bottles, from what they’re made of to how to use them. We’ll also answer some frequently asked questions about aluminum airless bottles.

Submit a Quick Quote

You May Also Like

Find more airless pump bottles, we have a wide range of them. Please don’t hesitate to contact us today. Our professional sales team will support your business 24/7 online.